Get ready to be amazed by some of Grandma’s never-before-seen tricks for unlocking the full potential of your wood-fired oven! Discover well-kept secrets on how to get to know and use your oven better, and become a true wood-fired cooking expert.

Read moreOur wood-fired ovens for bakeries.

This type of bread oven is traditionally distinguished by the presence of a heavy cast iron part, the throat. This angled removable part is installed and oriented over an opening between the fire box and the baking room.

Once the desired temperature has been reached, the baker removes the throat and covers the opening with a cast-iron disc or a bowl of water.

The advantages of throat ovens: comfort and productivity.

In a throat oven, the flame passes through the cooking chamber. It is therefore a direct-heating oven and qualifies as wood-fired bread.

With this throat system, the wood-burning and bread-baking zones are distinct. Concretely, this avoids the need for the baker to remove the embers and brush the floor after each batch.

In addition, he can easily restart a fire by conserving the embers and ashes in the fire box.

Thanks to the high inertia of our bread ovens, it is possible to bake several batches in succession without having to reheat, thus maximising both productivity and wood consumption.

As France’s leading manufacturer and exporter of wood ovens, Four Grand-Mère presents 3 types of static floor ovens:

• Throat ovens with lower fire box

• Throat ovens with lower fire box for conveyor belt loading

• Throat ovens with side fire box

All our ovens of this type are made in our workshops with a 6 cm thick brick paver floor and an 8 cm thick vault, in chamotte or brick, according to your preference

Our different models

Four Grand-Mère, France's leading manufacturer and exporter of wood-fired ovens, offers you 3 types of static floor ovens.

All are made in our workshops with a 6 cm thick brick base and an 8 cm thick vault, in chamotte or brick, as required.

Firebox under the baking chamber

The main advantage of lower throat ovens is that they require less space in the bakehouse, because the fire box is located under the oven floor. As needed, the baker orients the throat to direct the flame to the different zones of the baking chamber.

FBOUL1400GI

FBOUL1400GI

|

FBOUL2100GI

FBOUL2100GI

|

FBOUL2102GI

FBOUL2102GI

|

FBOUL2802GI

FBOUL2802GI

|

FBOUL2803GI

FBOUL2803GI

|

FBOUL3503GI

FBOUL3503GI

|

|

|---|---|---|---|---|---|---|

| Surface area of sole (m²) | 1,53 | 2,52 | 3,25 | 5,46 | 4,72 | 7,30 |

| External dimensions D x W x H (m) | 1,77 x 1,77 x 2,12 | 2,59 x 1,77 x 2,12 | 2,43 x 2,47 x 2,17 | 3,06 x 3,16 x 2,17 | 3,13 x 2,47 x 2,17 | 3,73 x 3,16 x 2,31 |

| Baguettes per batch | 21 | 35 | 45 | 76 | 66 | 102 |

| Number of 500 g loaves per batch | 14 | 22 | 29 | 49 | 42 | 65 |

| See the product | See the product | See the product | See the product | See the product | See the product |

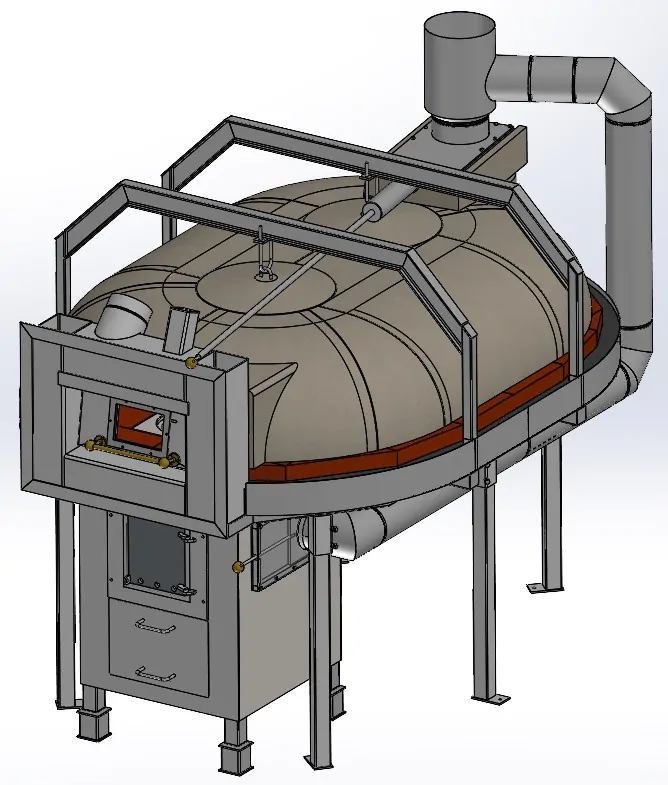

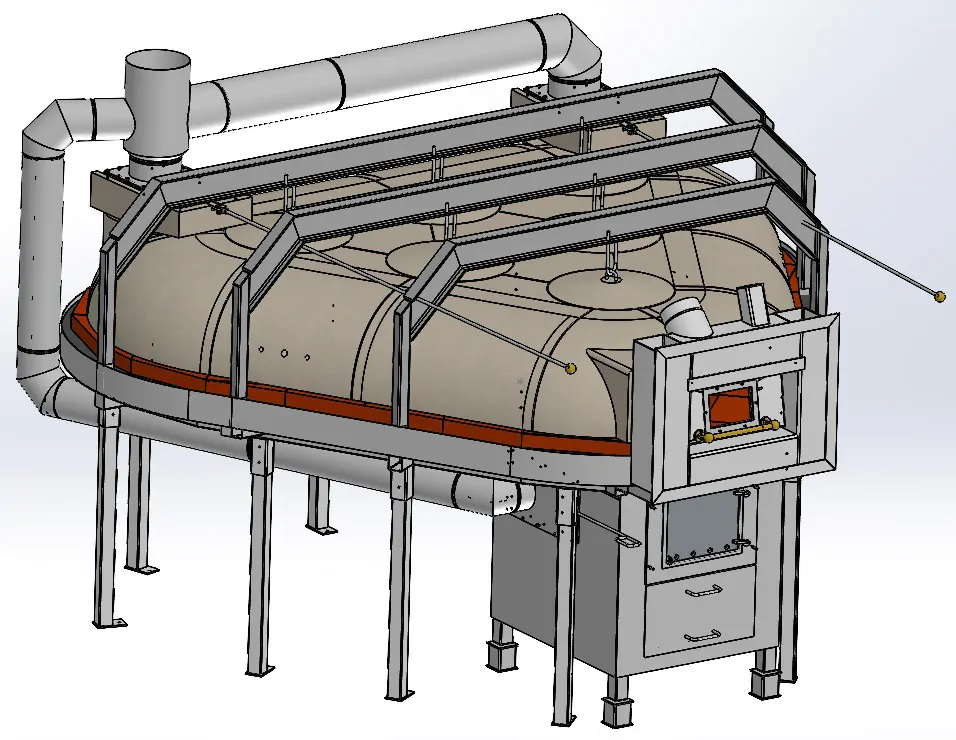

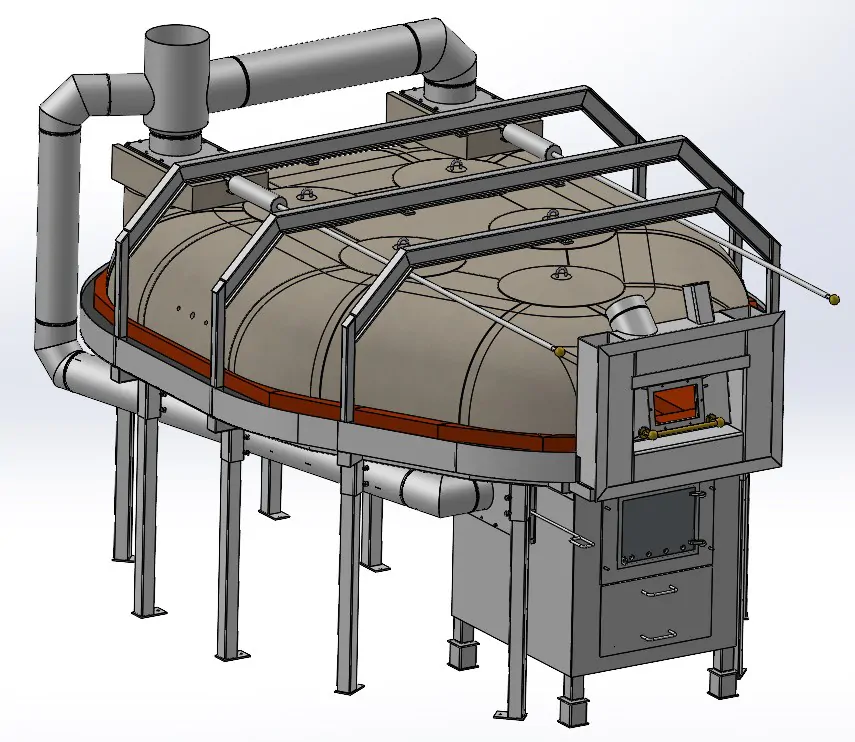

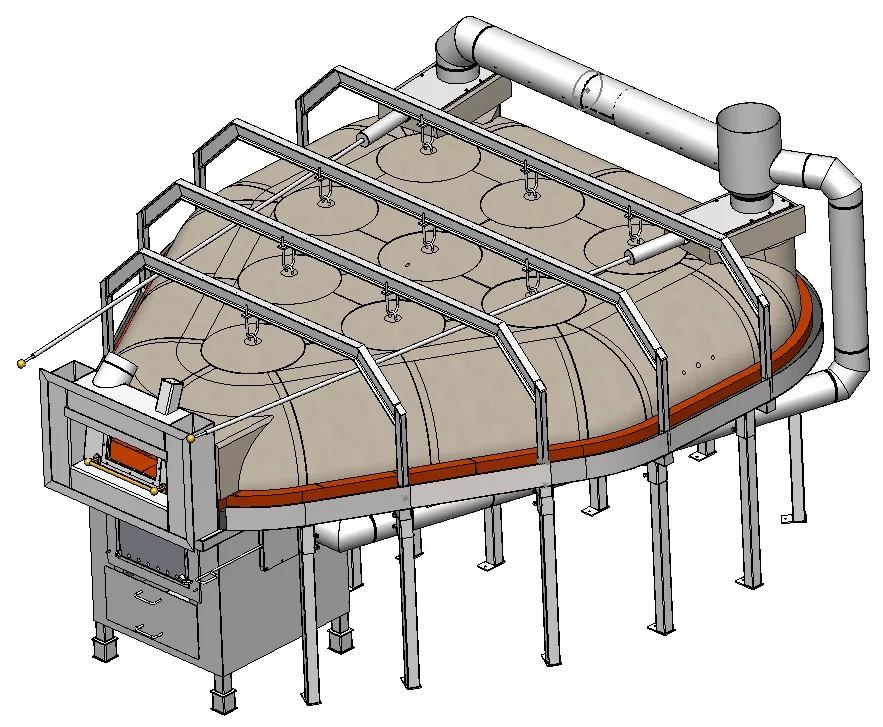

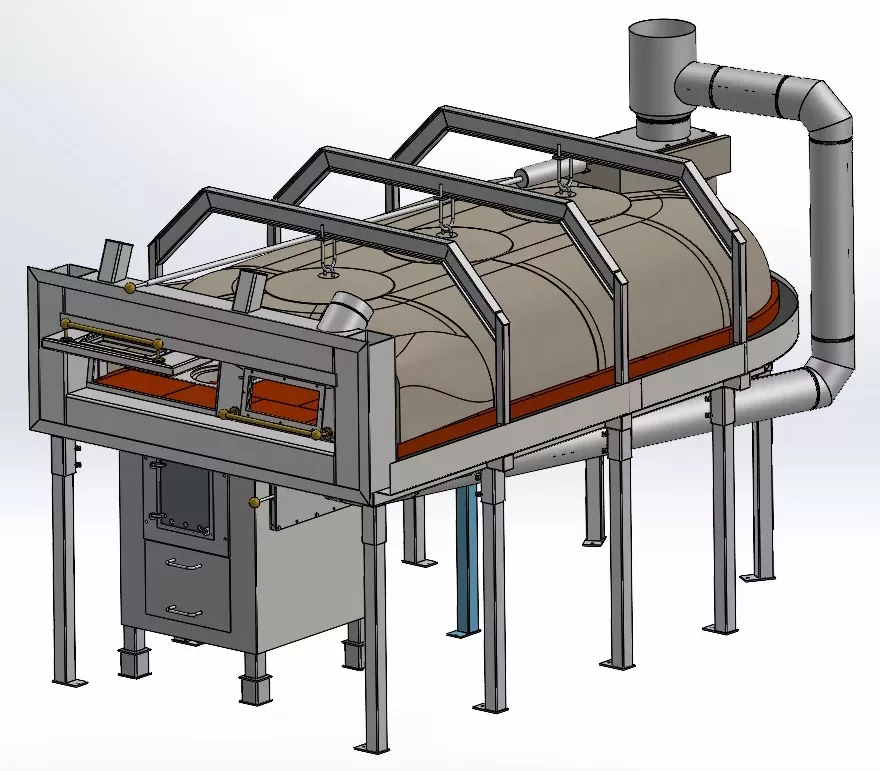

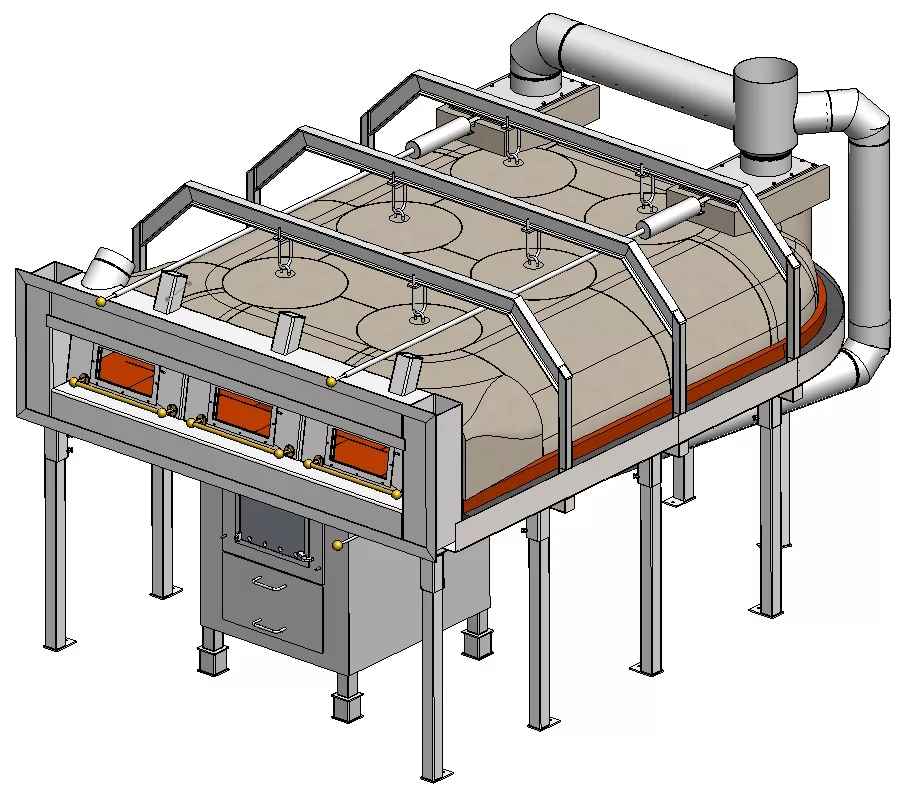

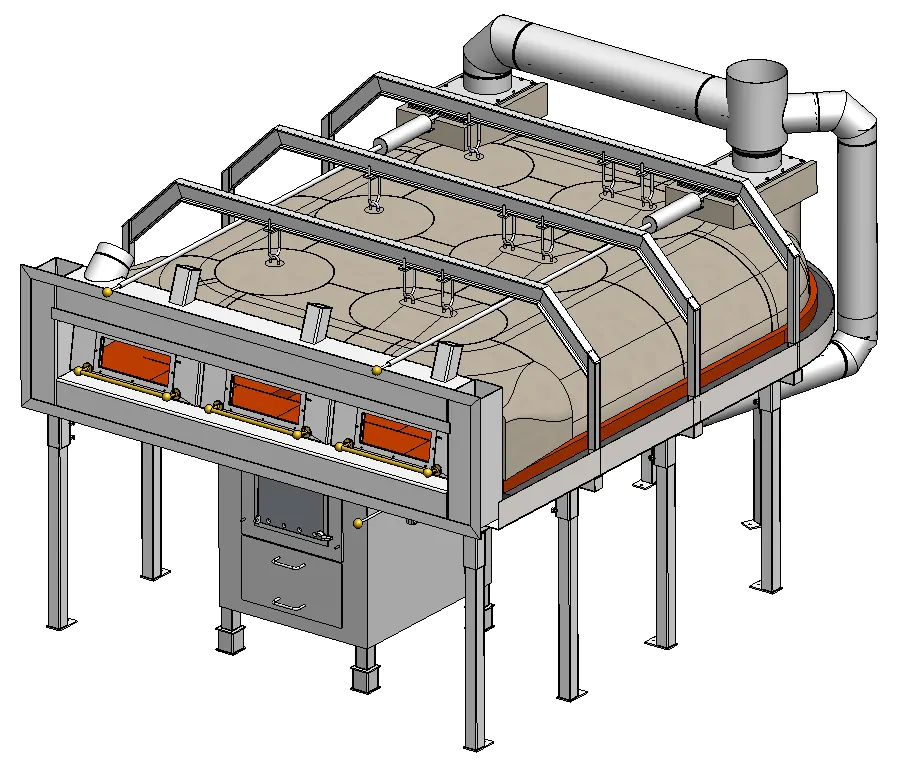

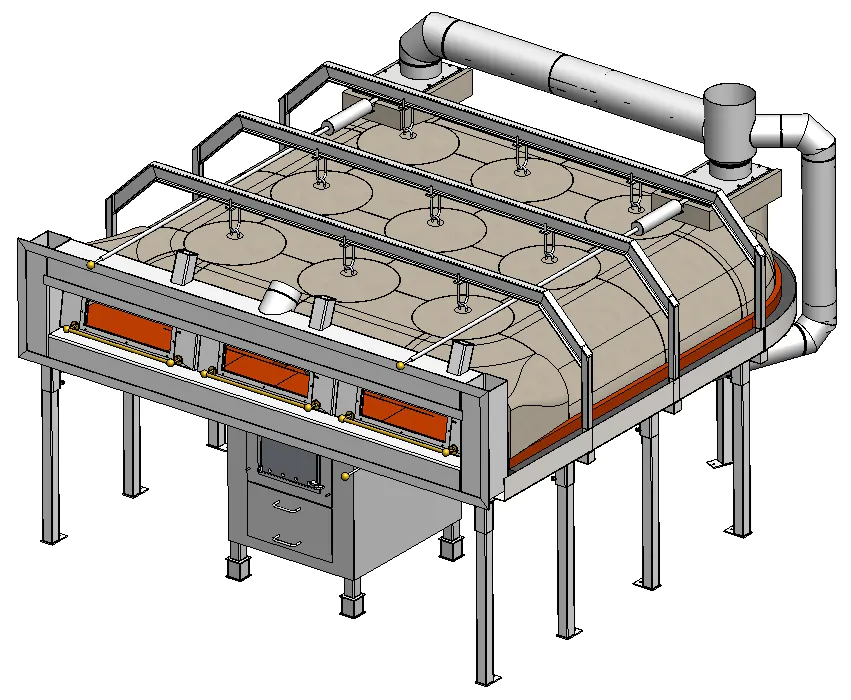

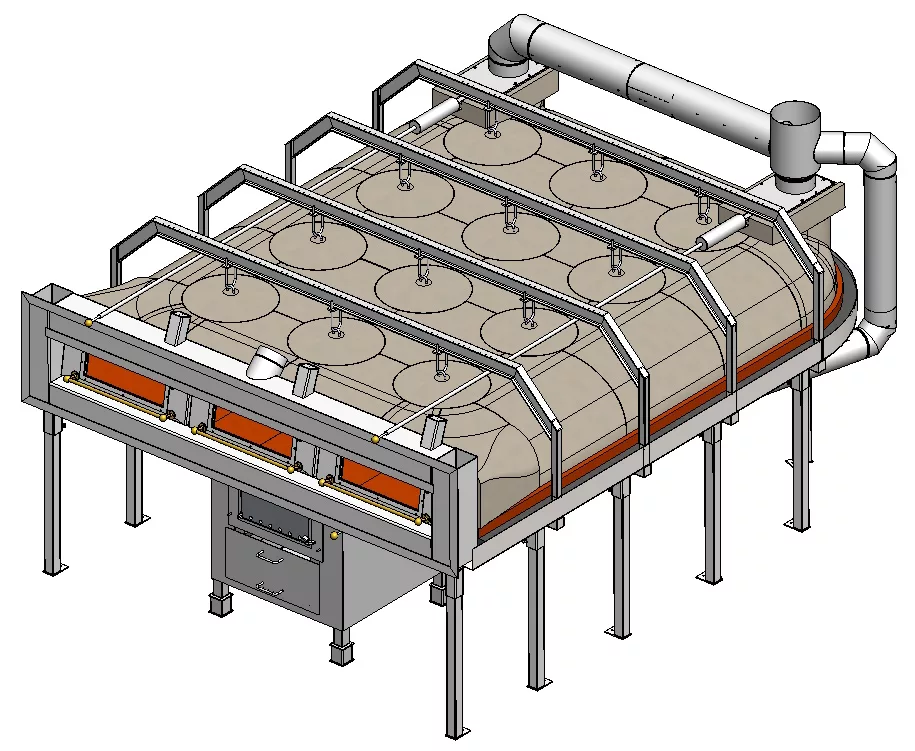

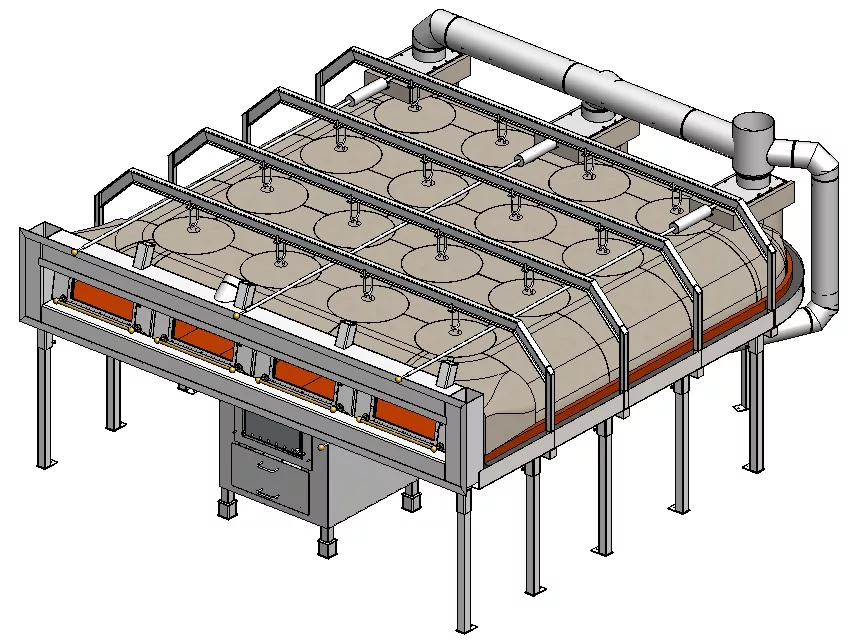

Throat ovens with lower fire box for conveyor belt loading

The lower fire box principle is also very interesting for conveyor belt loading, because the heat is well distributed.

Whether square or rectangular in shape, ovens in this category are especially well designed for conveyor belt loading, even though peel loading is also possible.

Always tailor-made, the oven conveyor belt is not manufactured by Four Grand Mère. However, on request, we can provide it and install it at the same time as your oven.

SP1428GI

SP1428GI

|

SP1926GI

SP1926GI

|

FSPC2126GI

FSPC2126GI

|

FSPC2626GI

FSPC2626GI

|

FSPC2633GI

FSPC2633GI

|

FSPC3333GI

FSPC3333GI

|

|

|---|---|---|---|---|---|---|

| Surface area of sole (m²) | 3,54 | 4,74 | 5,20 | 6,60 | 8,50 | 10,90 |

| External dimensions D x W x H (m) | 3,50 x 1,77 x 2,12 | 2,95 x 2,26 x 2,20 | 2,95 x 2,48 x 2,20 | 2,95 x 2,95 x 2,31 | 3,65 x 2,96 x 2,31 | 3,66 x 3,66 x 2,31 |

| Baguettes per batch | 50 | 66 | 74 | 92 | 119 | 153 |

| Number of 500 g loaves per batch | 32 | 43 | 47 | 59 | 76 | 98 |

| See the product | See the product | See the product | See the product | See the product | See the product |

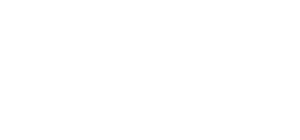

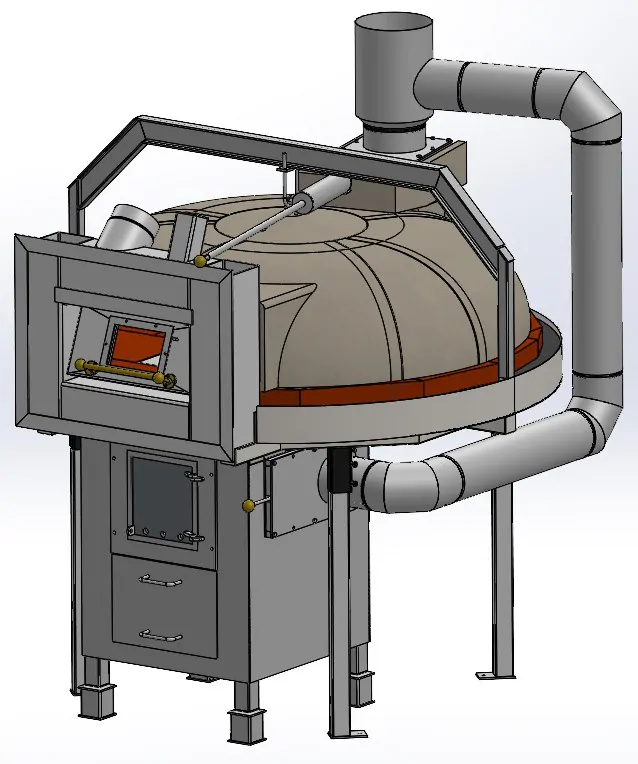

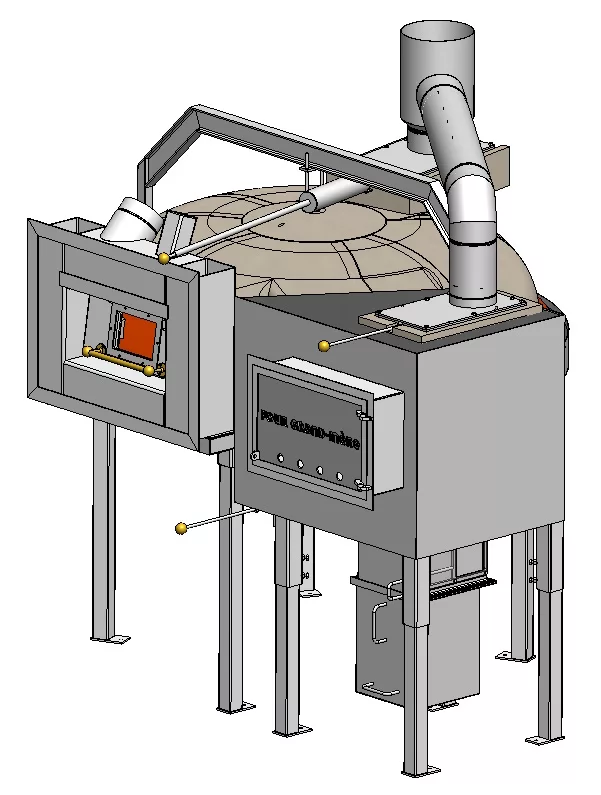

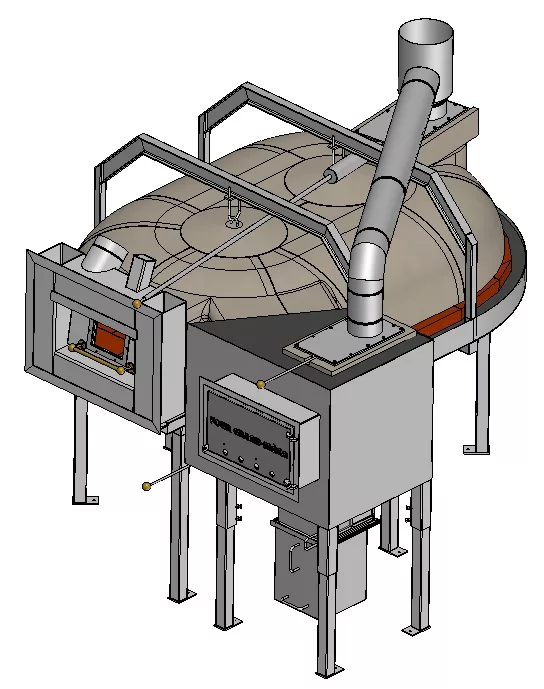

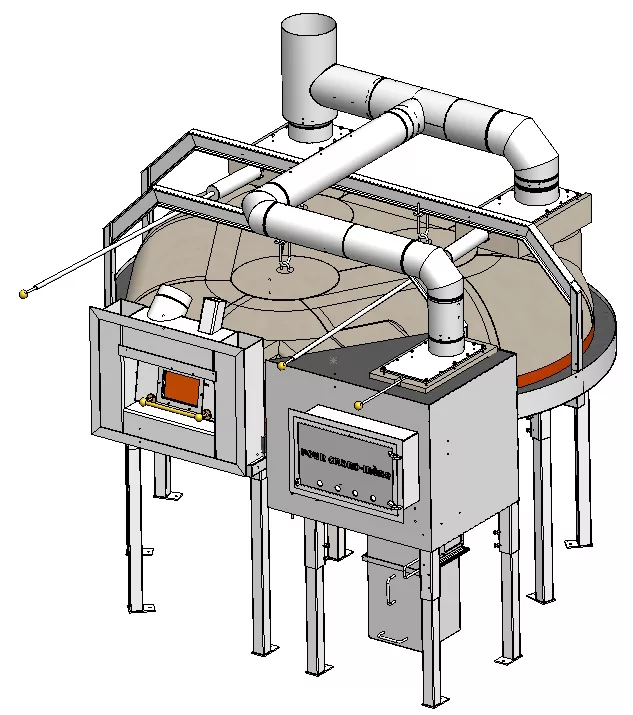

Throat ovens with side fire box

Four Grand-mère’s side throat ovens represent a modern evolution of the traditional throat ovens, which avoid having to handle the cast-iron throat.The fire box is located at the level of the baking chamber, to the right or left of the loading door, as preferred. If you have a sufficiently large bakehouse, this type of oven has a lot of advantages:

• The fire box at human height facilitates the supply.

• The baker does not receive the heat from the fire box in the legs when putting the product in or taking it out of the oven.

• The side fire box offers a great flexibility of use

FBOUL1400FL

FBOUL1400FL

|

FBOUL2100FL

FBOUL2100FL

|

FBOUL2102FL

FBOUL2102FL

|

FBOUL2802FL

FBOUL2802FL

|

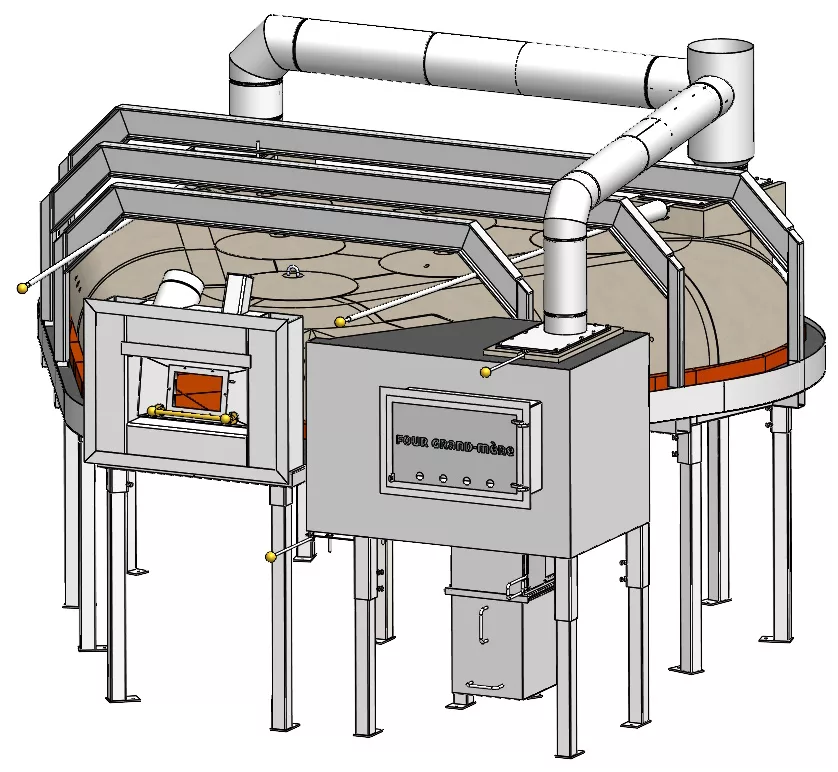

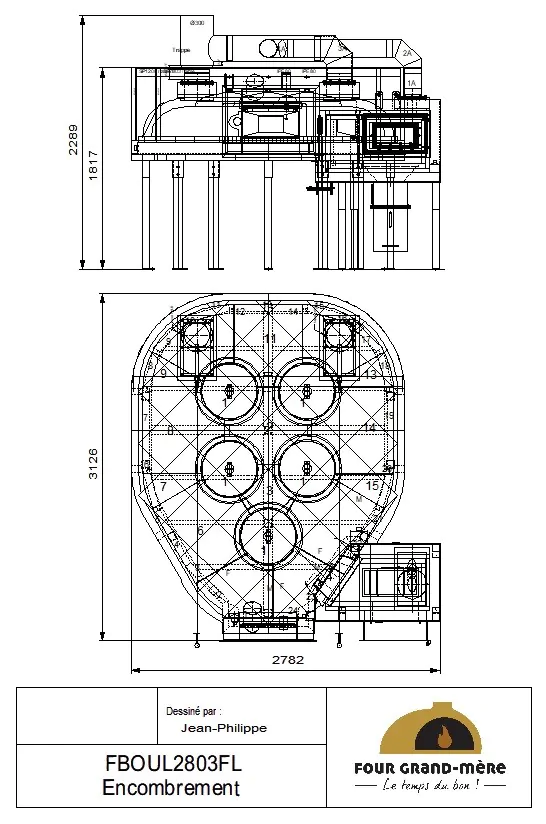

FBOUL2803FL

FBOUL2803FL

|

|

|---|---|---|---|---|---|

| Surface area of sole (m²) | 1,53 | 2,52 | 3,25 | 5,46 | 4,72 |

| External dimensions D x W x H (m) | 1,82 x 2,25 x 2,21 | 2,52 x 2,24 x 2,21 | 2,43 x 2,58 x 2,21 | 3,03 x 3,16x 2,17 | 3,13 x 2,78 x 2,29 |

| Baguettes per batch | 21 | 35 | 45 | 76 | 66 |

| Number of 500 g loaves per batch | 14 | 22 | 29 | 49 | 42 |

| See the product | See the product | See the product | See the product | See the product |

Supplies and equipment included

options

Embellished with beautiful ears of wheat, this cast-iron door features an automatic closing system, so that the baker can open and close it with his peel. You can also use a handle with a counterweight to manipulate it in a more traditional, effortless way.

We reworked the original model in our workshops to integrate a glass section and a lamp in order to illuminate the baking chamber.

The brick roof option can substitute the chamotte roof with a refractory brick roof. This change brings the unique advantages of refractory brick, such as better heat retention and distribution, as well as optimal thermal radiation.

The brick roof thus ensures more homogeneous baking and better-quality bread.

Four Grand-Mère offers a custom-made stainless steel facing for its bakery ovens. This facing improves the appearance and hygiene of your oven by providing a design to suit your specific requirements. Made of stainless-steel sheets, it is long-lasting, resistant and easy to clean.

It also offers a professional finish, and adds a modern, elegant touch to your oven.